Challenge

Design and fabricate a machine that allows users to make homemade, additive-free almond milk.

Demo Day

Almond Press without Milk

Almond Press with Milk

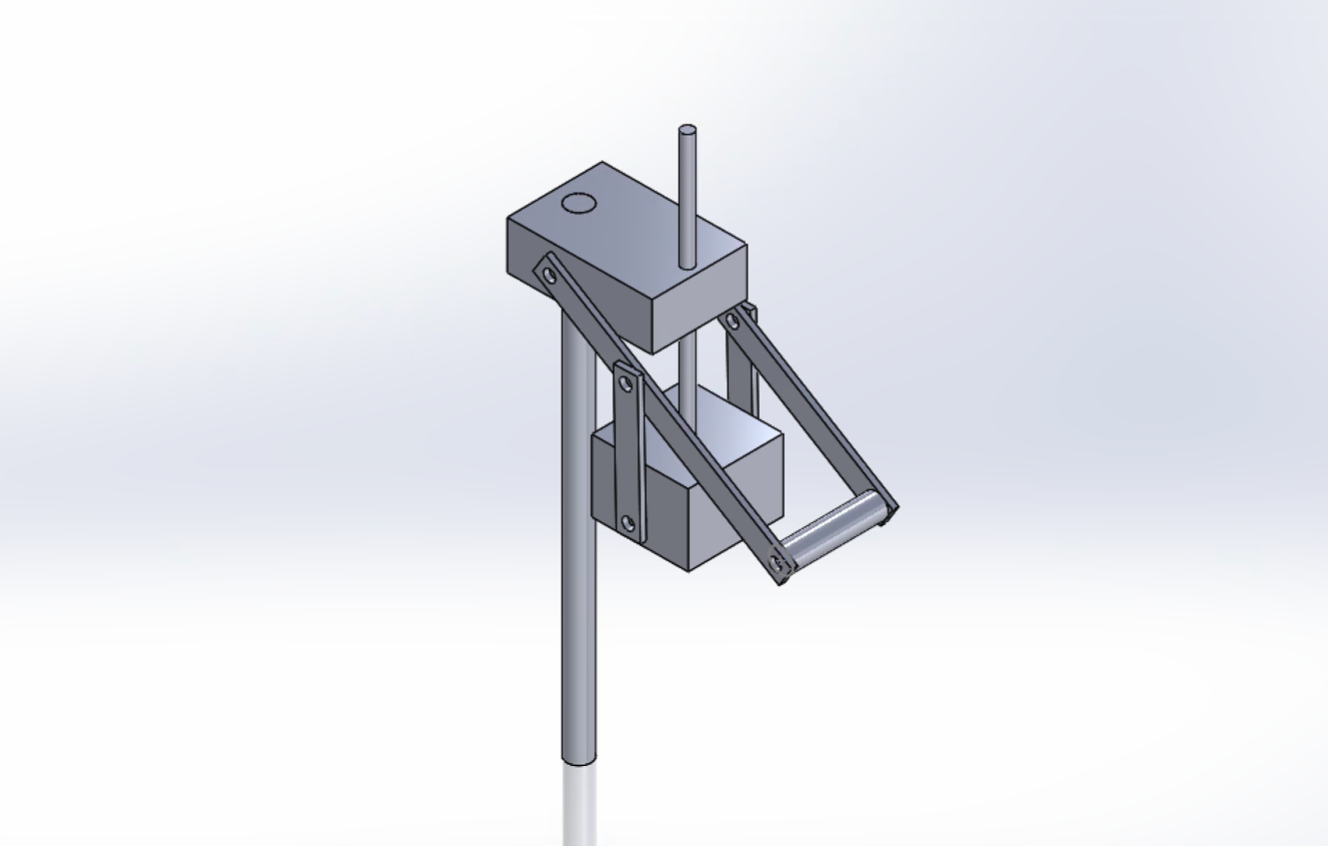

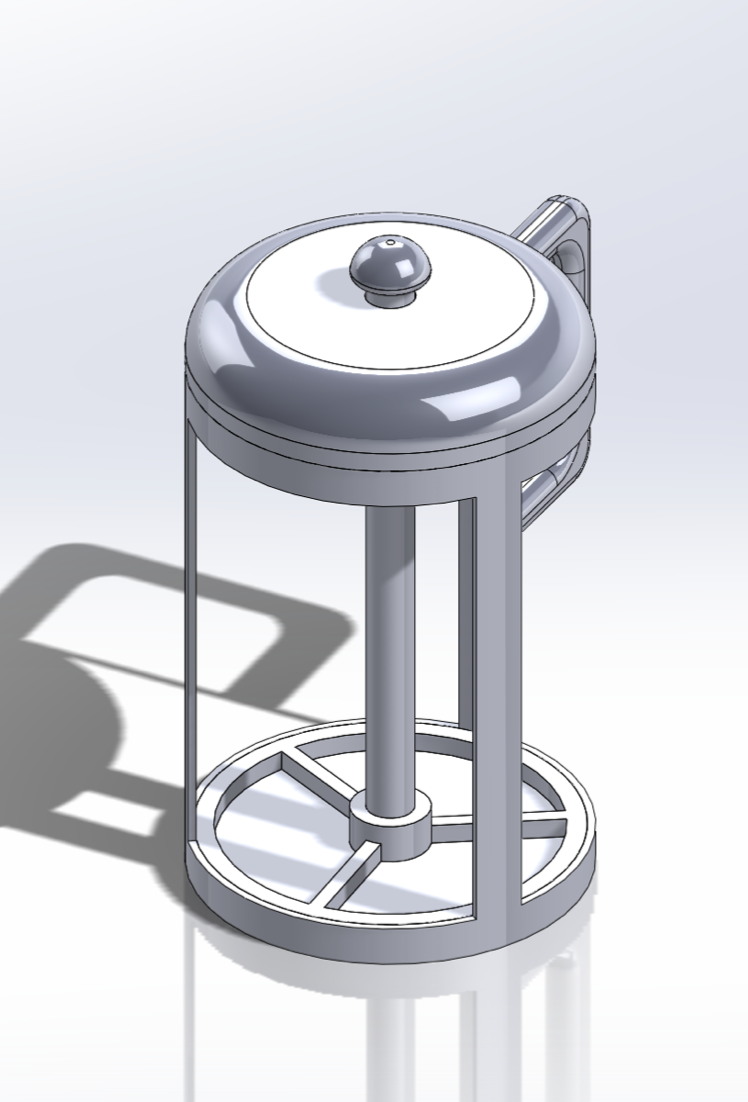

CAD Model

Project Overview

For my Introduction to Engineering class, we were tasked to design and develop ingenious and innovative solutions for the following theme: Engineering Improved Quality of Life.

Through interviews and in-depth research, our team stumbled on a compelling problem and user group regarding almond milk: current technology to make homemade, additive-free almond milk is time-intensive, messy, and inefficient. Thus, we created the Almond Press: a one-of-a-kind almond milk maker inspired by can crushing and juice press technologies. The primary design constraints were time and experience. We had less than 7 weeks to design and present a fully-functioning product. Furthermore, this was the first time my teammates and I encountered the design process, rapid prototyping, CAD, and fabrication.

This project threw me headfirst into the previously unexplored territory of engineering and product design. But, it was an incredible experience and always a fun story to tell!

Design Process

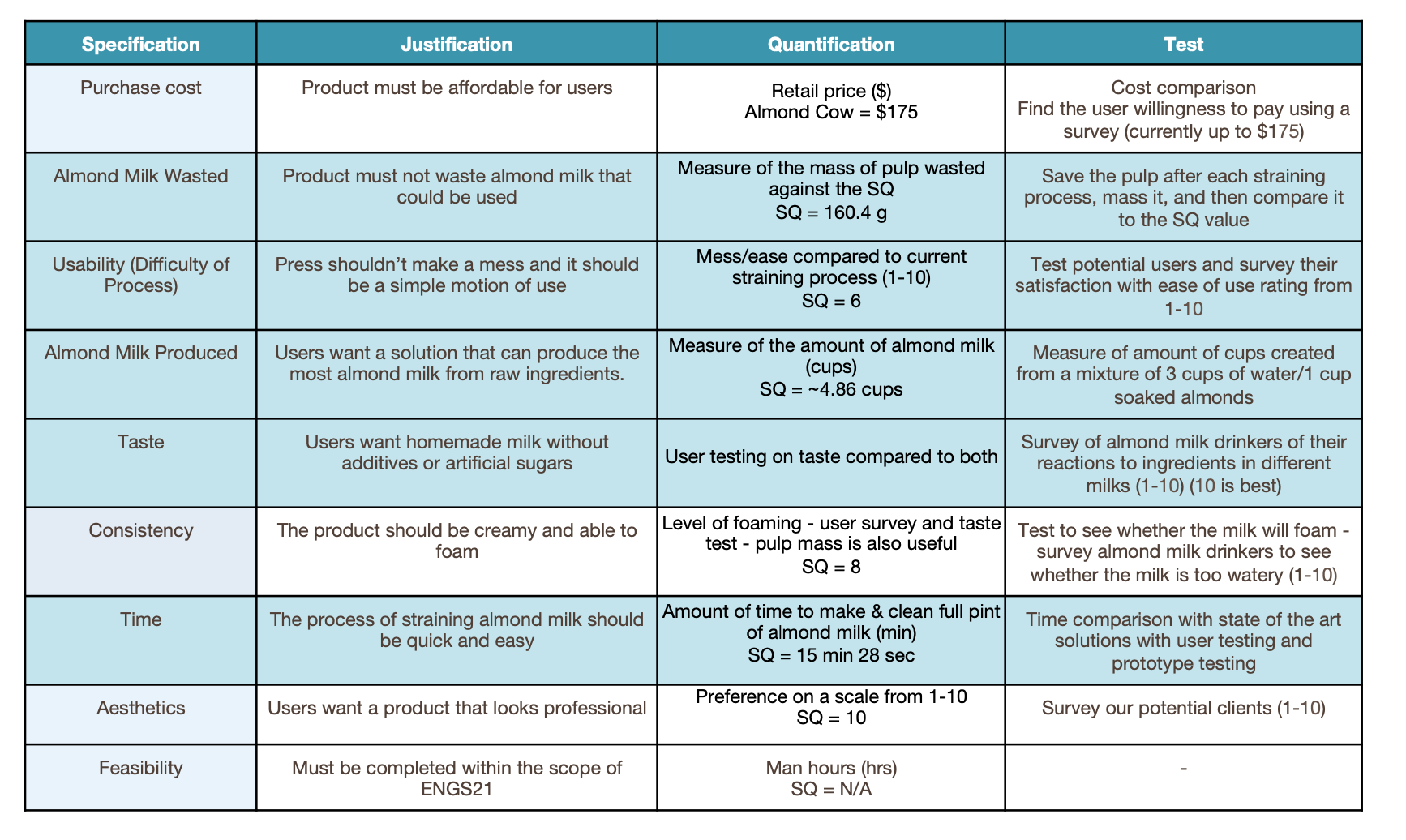

We researched countless juice pressers for all kinds of organic materials: oranges, apples, tomatoes, coffee beans, tea leaves, and cookies. We also performed benchmark testing and analyses for state of the art technologies: commercial "on the shelf" almond milk, the homemade almond milk process, and other almond milk makers.

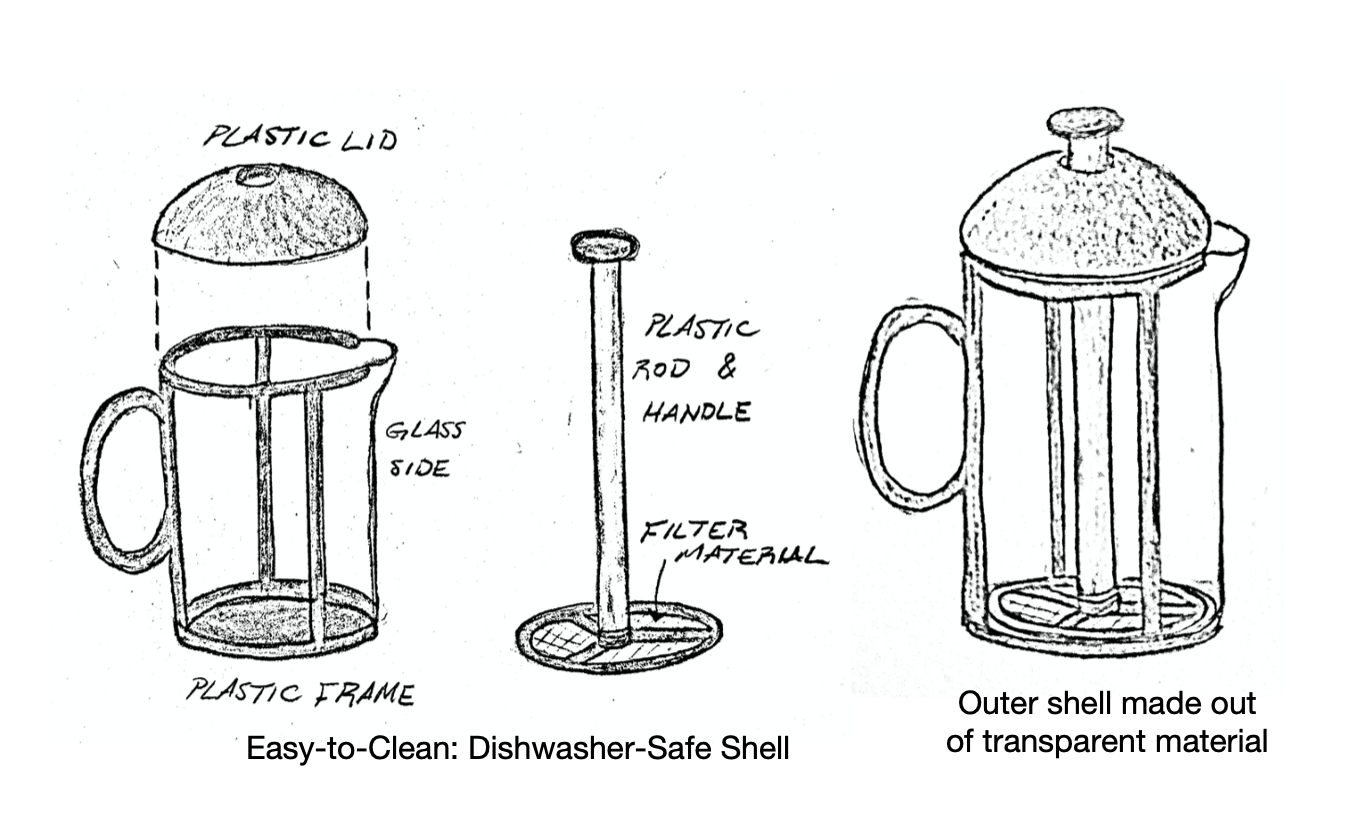

Our initial prototypes were based off of the French Press for coffee. As a team, we were really attached to this design concept, but as we took it from drawings to CAD to assembly, we realized that it was not an effective nor feasible solution. We ultimately decided to pivot from this French Press inspired design concept, and pursued other pressing technologies for further inspiration.

In the end, our Almond Press was a unique machine inspired by can crushing and juice press technologies. After blending almonds and water in a high-speed blender, the user would pour the mixture into our strainer lined with nylon mesh. Then, the top presser, attached to a user-controlled lever arm, would crush and squeeze the excess liquid from the almond pulp, filtering the milk into a cup below.

Key Takeaways

This project is where I experienced many of my "firsts" as a mechanical engineer and designer. It was the first time I heard about iterative design, the first time I made prototypes using foam core, the first time I went into the machine shop, the first time I used SolidWorks, among many more.

This was also my first serious academic experience working with a team for 10 weeks. It was definitely a challenge, but I was able to learn so much about myself (strengths, weaknesses, how I function in a team), as well as gain a general understanding of what works well versus what doesn't in a team with so many differences (i.e. class year, engineering experience, academic interests).

This project served as an unforgettable introduction to the world of engineering, design, and collaboration. And for me, our Almond Press is a product (and experience, really) that I'm genuinely proud of and also delighted by.

Skills & Documentation

Skills: Rapid Prototyping | Machine Engineering | SolidWorks | Design for Assembly | GD&T | CNC Mill | CNC Lathe

Documentation: Executive Summary, Pitch Presentation, Written Report

A special thanks to my teammates: Dan Phan, Himadri Narasimhamurthy, Maya Clarke-Brunetto, Bob Wang, & Shinar Jain

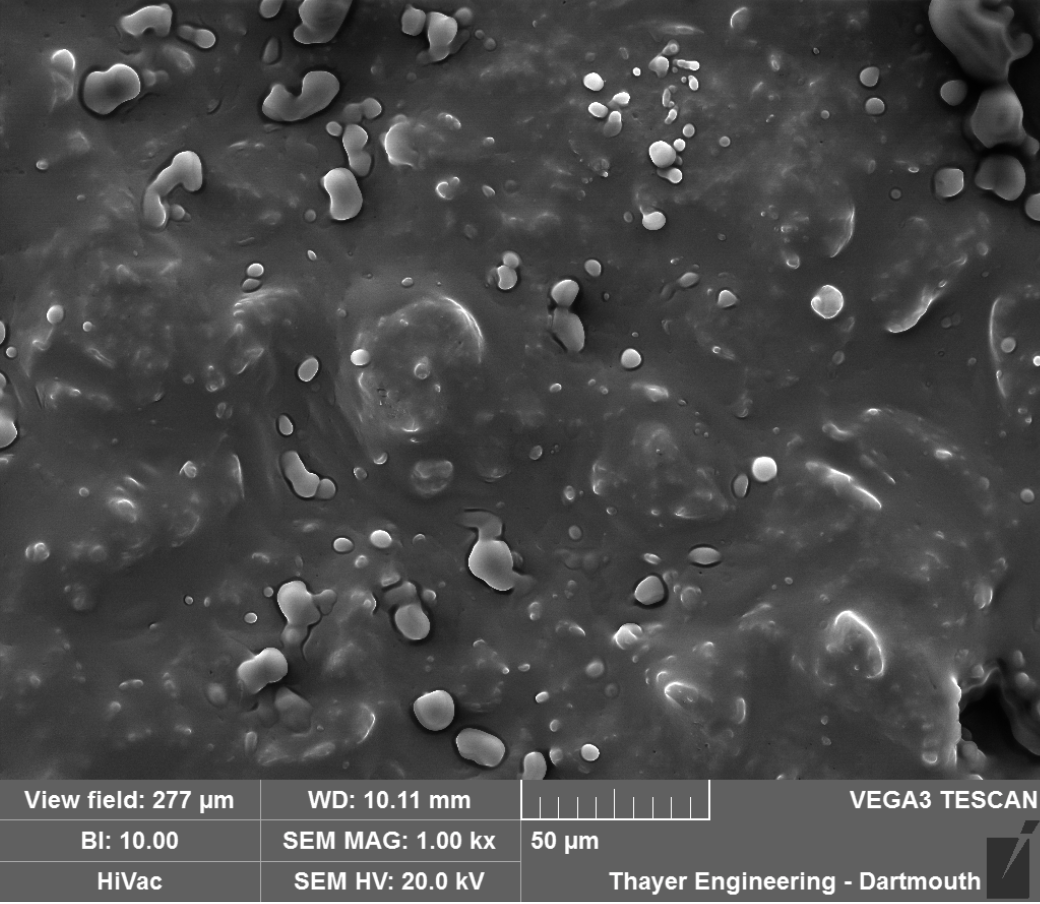

SEM Photo of Almond Milk (1000x Magnification)

Design Specifications Matrix

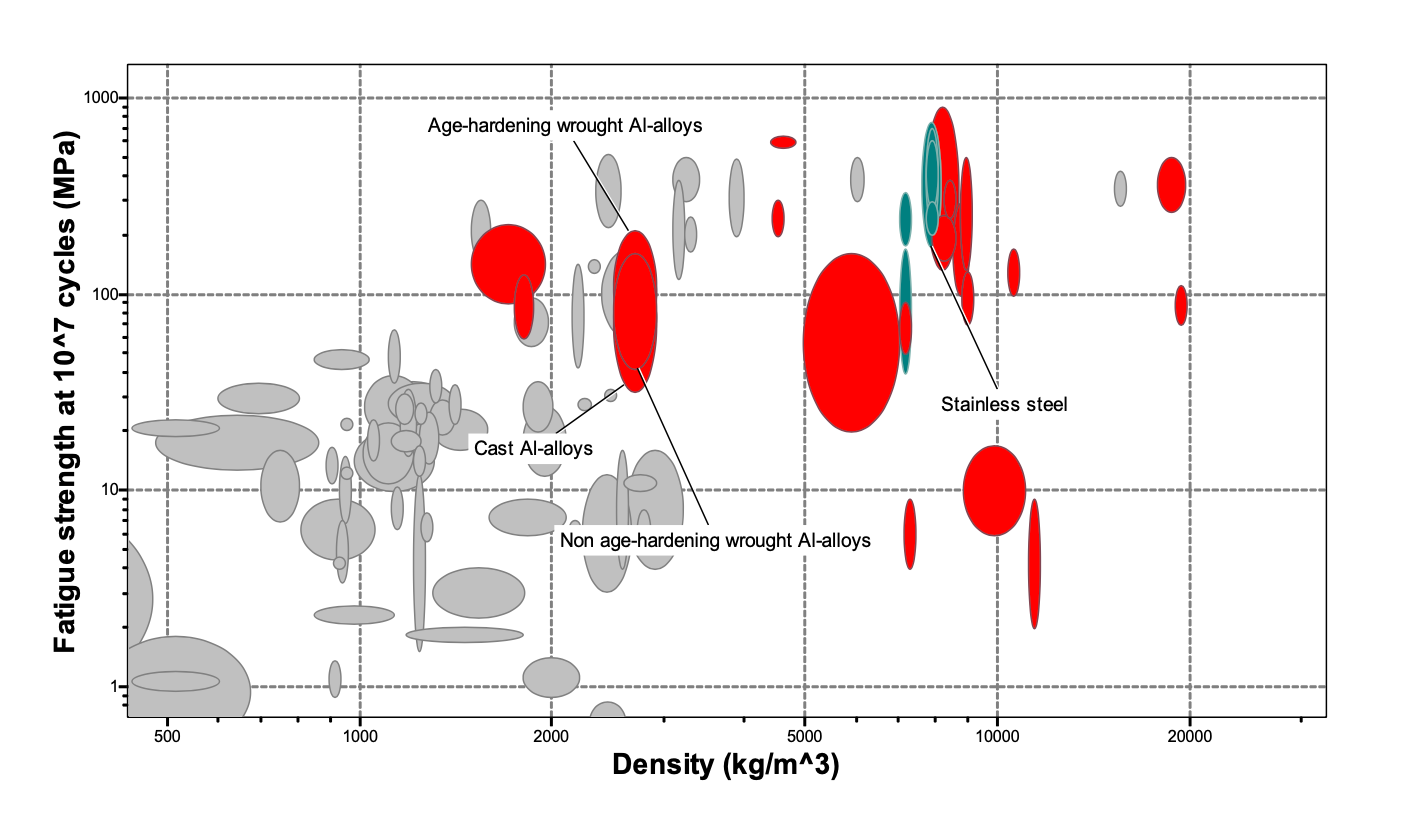

Materials Analysis

French Press: Prototype

French Press: CAD

French Press: Drawings

Almond Cow