Challenge

Fabricate a Stirling engine that optimizes fuel efficiency, given only the technical drawings of the individual parts.

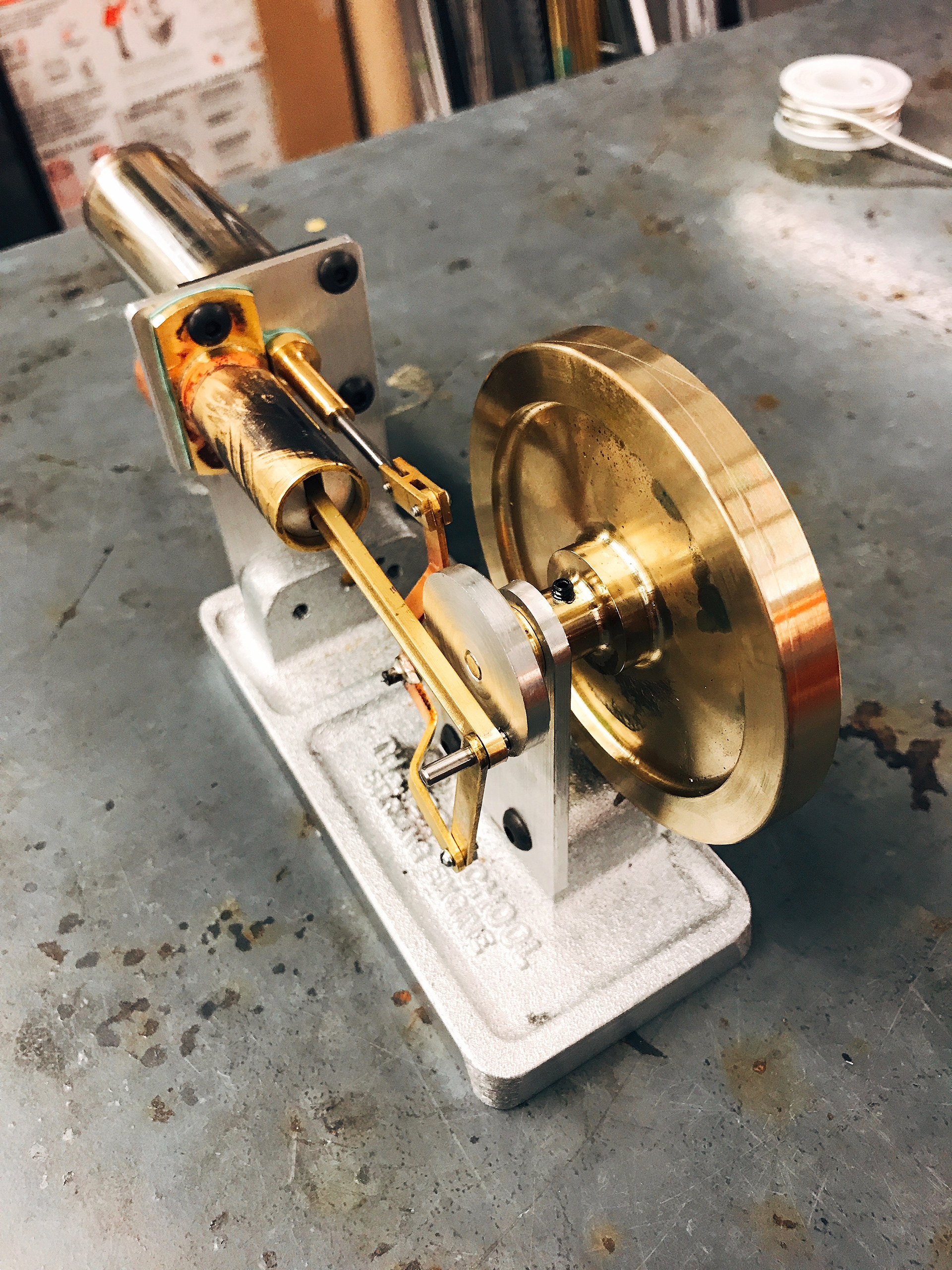

Isometric View

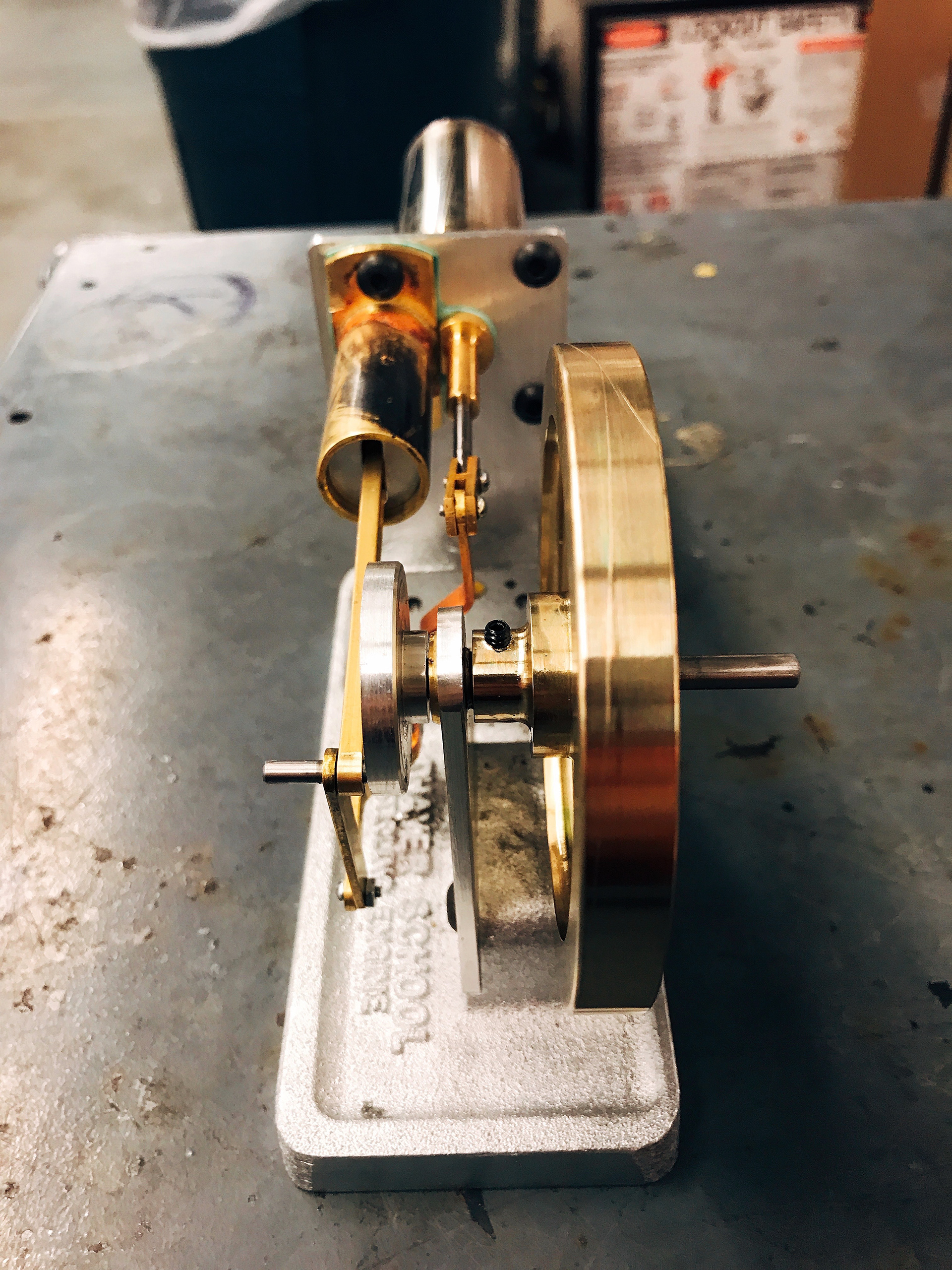

Side View

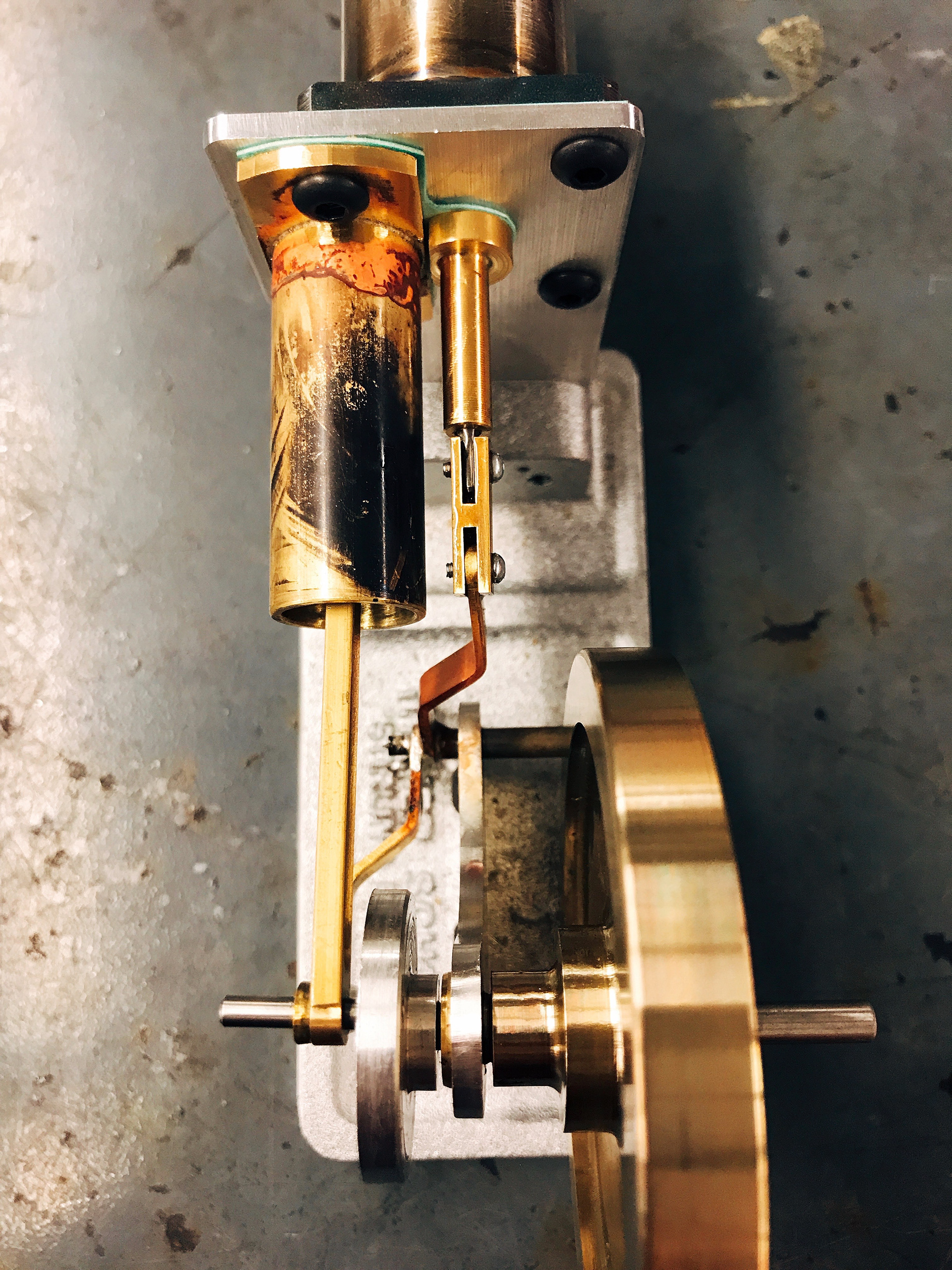

Top View

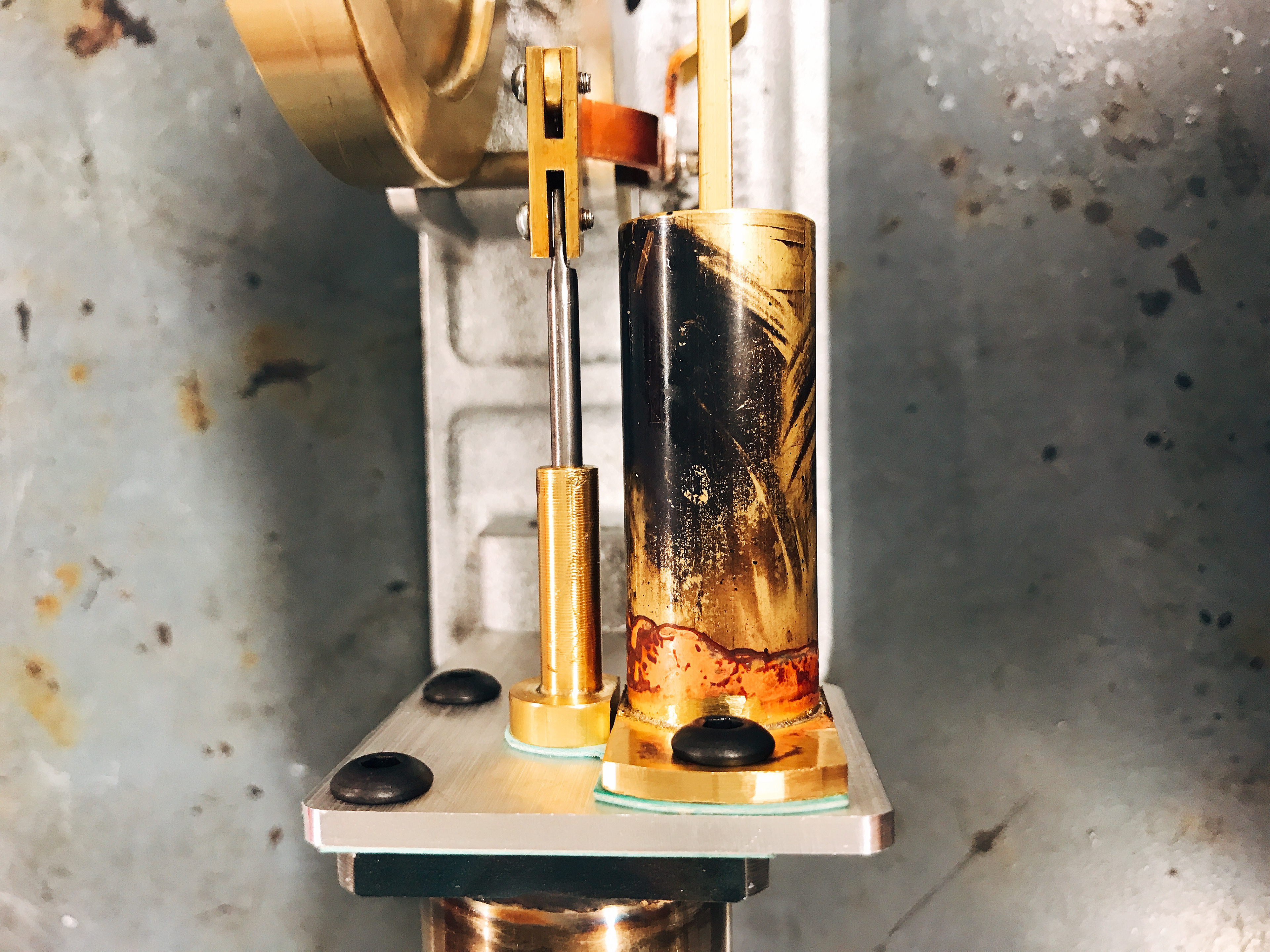

Close Top View

Project Overview

For my Thermodynamics class, we were tasked with building a Stirling engine. We were given technical drawings of the individual parts and expected to fabricate the engine using mills, lathes, and other equipment in the machine shop. Beyond pure functionality, there was also a competition to evaluate who could build the engine with the fastest flywheel RPM.

This project was an exciting, hands-on introduction to thermodynamics, and it was a really great way to gain proficiency with the equipment in the machine shop.

Machining Process

First, we were given a sand-casted base for the engine, which we had to face and drill and tap holes to exact specifications using the mill. To create the side plates, we set up a program on the mill that machined the specific shape and drilled clearance holes. We also used the mill to drill and tap holes in the flywheel.

The heat transfer cylinder was fabricated using the lathe, which taught us how to face, turn, cut off, drill holes, and tap holes. We also used the lathe to fabricate the guide bushing bearings. Both of these parts had very tight tolerances, so it was a challenge to fabricate them within the provided specifications.

Once all of the individual parts were machined, we had to assemble the engine. The assembly was actually one of the most difficult parts because the fit and orientation of each piece influenced if the engine would be able to successfully run as well as the flywheel RPM.

Finally, we put fuel in the tank and lit the wick with a blowtorch. The heat from the fuel creates a temperature differential within the heat transfer cylinder, which then causes the piston to oscillate, ultimately driving the movement of the flywheel. Testing the engine's fuel efficiency included measuring how long it took to burn a certain amount of fuel as well as the flywheel RPM.

Key Takeaways

This project was a cool, hands-on experience that gave me a lot of exposure to the machine shop. After fabricating the Stirling engine, I felt confident and knowledgable using the mill and the lathe. I also learned a lot about reading technical drawings as well as the immense precision that fabrication and assembly require.

Overall, this project was a great way to see the applications of thermodynamics first hand and gain a deeper understanding of the Stirling cycle. (And I also won a $20 gift card to a local gelato place for having the 4th most fuel-efficient engine!).

Skills

Machine Engineering | CNC Mill | CNC Lathe